China’s ballistic composites market grows 10.1% CAGR, fueled by military, aerospace, and protective gear demand, with advances in lightweight armor tech.

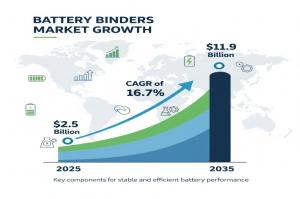

NEWARK, DE, UNITED STATES, August 11, 2025 /EINPresswire.com/ — The global Battery Binders Market is on a transformative growth trajectory, poised to expand from USD 2.5 billion in 2025 to USD 11.9 billion by 2035, registering a remarkable 16.7% CAGR. As manufacturers in electric vehicles, energy storage, and portable electronics push the boundaries of performance, safety, and sustainability, advanced binder technologies are becoming indispensable to their success.

Market Momentum Driven by Electrification and Performance Demands

With lithium-ion batteries at the heart of mobility, energy, and consumer electronics, binders are no longer a passive component—they are an active enabler of battery longevity, adhesion, thermal stability, and safety. Market growth is propelled by rapid electrification across industries, rising demand for fast-charging capabilities, and the global transition toward cleaner energy solutions.

Manufacturers are increasingly adopting water-based and advanced polymer binder chemistries to meet stringent performance criteria, while aligning with evolving environmental standards. The expanding electric vehicle (EV) ecosystem, bolstered by global policy support and multi-billion-dollar gigafactory investments, is creating sustained demand for high-quality binders that can handle extreme mechanical and thermal cycling.

Segment Leadership – PMMA at the Forefront

Within the type segment, Polymethyl Methacrylate (PMMA) leads with 28.6% market share in 2025, valued for its exceptional adhesion, chemical resistance, and compatibility with electrode materials. Its structural stability and lightweight nature reduce degradation, essential for EVs and portable electronics.

Ongoing research into PMMA formulations for both anode and cathode technologies ensures this segment’s continued relevance as manufacturers seek to maintain electrode cohesion in high-energy-density battery designs.

Electric Vehicles – The Largest Application Driver

Electric vehicles dominate the application segment with a 41.9% share, reflecting their reliance on high-performance lithium-ion batteries. Here, binders directly impact energy density, range, and lifecycle performance, making them a critical focus for automakers.

Governments’ decarbonization goals, coupled with EV-specific battery innovation, have accelerated binder demand. Efforts to enhance recyclability and environmental safety in battery production are further influencing binder selection and formulation.

Automotive – The Leading End-Use Sector

The automotive industry, holding 36.7% of end-use share, is the most significant consumer of battery binders. As EV adoption grows in both passenger and commercial fleets, automakers are working closely with binder suppliers to meet evolving specifications for safety, range, and durability.

Binder innovations are key to enabling long-range electric mobility and ensuring compliance with international safety standards—critical factors in global automotive competitiveness.

Challenges for Manufacturers – Balancing Compliance, Cost, and Performance

While demand is strong, battery binder producers face tightening environmental regulations, particularly regarding solvent-based and fluorinated materials. Compliance with NMP emissions standards and solvent recovery requirements can delay production timelines and increase capital investment.

Although aqueous binders offer a regulatory advantage, their integration into high-voltage or extreme-temperature battery applications remains complex. Manufacturers must navigate performance-compatibility challenges without compromising commercial viability or production speed.

Additionally, high production costs—driven by advanced polymer expenses, tight quality control, and raw material volatility—are a major restraint. Cost-effective scalability remains an industry-wide challenge, especially for high-volume, price-sensitive applications like entry-level EVs.

Opportunities in Emerging Chemistries and Water-Based Systems

The diversification of battery technologies—such as silicon-rich anodes, lithium-sulfur, and sodium-ion—is creating new demand for binders capable of handling unique expansion ratios, ionic conductivity needs, and mechanical stresses.

Water-based systems, including SBR and CMC, are gaining adoption in anode applications for both automotive and consumer electronics. While high-voltage cathode compatibility is still being refined, hybrid aqueous formulations and crosslinked polymers are emerging as promising solutions.

Manufacturers that align with this shift toward non-toxic, energy-efficient, and sustainable binder systems will be well-positioned for long-term competitive advantage.

Regional Growth Highlights

Market expansion is global, with top growth rates recorded in:

• China – 22.5% CAGR, supported by large-scale cell manufacturing and localized binder supply chains.

• India – 20.9% CAGR, driven by domestic gigafactory projects and EV assembly growth.

• Germany – 19.2% CAGR, backed by European cell manufacturing clusters integrating advanced binders.

• UK – 15.9% CAGR, with rising adoption in niche chemistries and pilot production.

• USA – 14.2% CAGR, supported by government-backed energy storage programs.

Competitive Landscape – Innovation at the Core

The market is anchored by global chemical leaders and specialty materials companies:

• DuPont – Offering aqueous and solvent-based binders compatible with silicon, graphite, and lithium-metal anodes.

• BASF SE – Innovating polymer binders to minimize electrode swelling and boost energy density, including its Net-Zero Carbon Footprint Licity® anode binders launched in May 2023.

• Asahi Kasei & Zeon Corporation – Leading in SBR and PVDF binders for EV and ESS applications.

• Daikin Industries & Arkema – Specialists in fluorinated binders for high-voltage chemistries.

• Solvay S.A – Delivering PVDF binders with optimized dispersion for high-throughput manufacturing.

• Mitsubishi Chemical Corporation, LG Chem – Advancing binders for next-gen anode materials and in-house battery divisions.

• Lubrizol, SYNTHOMER PLC, Trinseo S.A – Providing customized chemistries for both electrodes.

• Targray, Industrial Summit Technology Corp – Supplying niche binder materials with competitive pricing and global reach.

Request Battery Binders Market Draft Report:

https://www.futuremarketinsights.com/reports/sample/rep-gb-22849

For more on their methodology and market coverage, visit https://www.futuremarketinsights.com/about-us.

Future Outlook – Strategic Imperatives for Manufacturers

As the Battery Binders Market moves toward a projected USD 11.9 billion valuation by 2035, manufacturers have a clear set of imperatives:

1. Invest in R&D for aqueous and hybrid binder systems that balance sustainability with high-performance requirements.

2. Collaborate closely with cell manufacturers to customize binder solutions for emerging chemistries.

3. Scale production efficiently to address cost constraints without compromising quality.

4. Integrate compliance strategies early in product development to minimize regulatory delays.

Related Insights from Future Market Insights (FMI)

Battery Materials Recycling Market – https://www.futuremarketinsights.com/reports/battery-materials-recycling-market

Battery Packaging Material Market – https://www.futuremarketinsights.com/reports/battery-packaging-material-market

Battery Materials Market – https://www.futuremarketinsights.com/reports/battery-materials-market

Editor’s Note:

The Battery Binders Market is witnessing steady growth, driven by surging demand for electric vehicles, energy storage systems, and portable electronics. Innovations in eco-friendly and high-performance binders are reshaping manufacturing standards. This evolving landscape presents vast opportunities for material developers and battery manufacturers worldwide.

Rahul Singh

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content “as is” without warranty of any kind. We do not accept any responsibility or liability

for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this

article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

![]()